People who sharpen blades with any regularity eventually learn to discern the quality of their edges. We each have the methods that work for us. For some ceremoniously and effortlessly, slicing thin magazines or the nearly extinct telephone book pages are popular ways of assessing an edge. Using super thin paper offers an auditory means for detecting even the most minor chips. Having the blade bite while sliding it on a thumb or fingernail is another quick, simple test. Then there’s the ever-popular – with some males anyway – arm-hair shaving. If you’re showing off, you’ll demonstrate how to whittle a single strand of hair! So, with all that said, how sharp is your knife, exactly? Great question!

“Adjectively Sharp” or Good Enough

Early on, the problem for me as a self-taught knife sharpening enthusiast was that I had no relative frame of reference for determining sharpness compared to other blades. I didn’t know what I didn’t know about how sharp an edge could get and how to measure it. Terms like wicked sharp, scary sharp, etc., mean nothing without some frame of reference. I call these terms “adjectively sharp” All I knew was that my edge was decent once I could shave arm hair cleanly. And good enough.

Objective Standard Frame of Reference

The job was complete once I could shave arm hair after using run-of-the-mill Arkansas stones and oil. For most of us, we sharpen until it’s good enough to perform the intended task, whether filleting a fish or cutting rope. Testing an edge by slicing paper is quick and easy, but the problem is which paper? How thick is the sheet? Is the paper coated? With the grain or against it? Push-cutting a blade through thin phone book paper is different than push-cutting 100 lb printer paper, but what does that mean? Which is sharper? Is shaving my fine arm hair the same as shaving thick bush-like arm hair?

YouTube, Internet Forums, Created Defacto Standard Sharpness Tests

With the emergence of the Internet, online forums, and YouTube channels, knife sharpening enthusiasts began to sort out simple, cost-effective ways to communicate the sharpness of their edges. To assess my edge vs. yours, virtually, clever reference standards have emerged based on specific products like a particular cigarette rolling paper. As it happens, successfully push-cutting a knife blade into a particular brand of cigarette paper means you have a very sharp edge. Anything less is immediately apparent. Of course, this particular test can be fooled with a useless superfine foil edge too, which means it’s sharp but folds like a lawn chair and dulls if you cut into anything solid. The cigarette paper test offers a standard reference upon which we can evaluate our edges on some level, but this still falls short of helping us to understand what it means.

But, How Sharp Is The Blade?

For me, the problem is determining relative sharpness against some consistent, repeatable standard. So, while I know my polished 6000-grit chef knife-edge glides effortlessly through a light catalog sheet of paper, what do I know? Well, I know it’s certainly a usable edge in the kitchen. And I also know that there are no chips or else I’d hear and feel them slightly interrupting the otherwise smooth slicing. One trap is that I could achieve this test with an improperly de-burred edge too, which means it would dull during first use on a cutting board, assuming the knife is sharpened adequately for durability too (i.e., de-burred).

Needed: A Standard Replicable Method For Determining Sharpness

What’s missing is a way to know, beyond doubt, that a particular effort, sound, or feel of the paper test is akin to some objective and quantifiable standard. Moreover, it would be nice to send our sharpened knife to another person knowing they will get the same result when they test the edge using the same method & scale. So we need a replicable process with as few variables as possible and a means for quantifying the results.

We need a method, and we need a standard measuring scale. If I measure and conclude a sharpness of 10 using method ABC, you should also get the same result using method ABC. Make sense? Once you know that a particular sharpness method equates to a well-known and repeatable standard, you know the relative sharpness of your edge. So, what standard should we use? That is another good question. That’s where BESS comes in. Let’s meet BESS.

The BESS Sharpness Test System

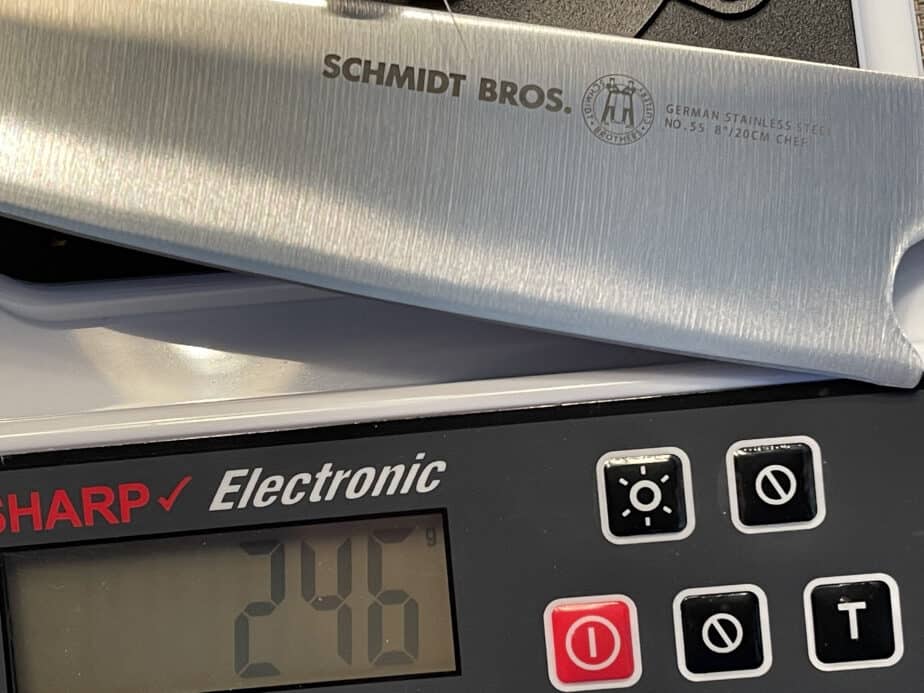

The BESS system is relatively easy to understand. You have a specially modified scale that measures grams that records the downward force required to sever a certified test media (resembles a piece of fishing line). After recording the amount of force in grams, the result compares with a published scale equating to typical commercial edges indicating relative sharpness. For example, most people would agree that a double-edge razor blade, out of the package, is very sharp. It is very sharp and requires very little force in grams to sever the media, which results in a low BESS number. Conversely, a regular butter knife is quite dull and requires a significant effort to sever the test media resulting in a high BESS number.

As you might imagine, there are many sharpness levels between a dull butter knife and a fresh double-edge razor blade. That is where the BESS C-Scale comes into play. The BESS C Scale is our standard of reference. Once you’ve sharpened and tested enough knives using a BESS tester, you quickly learn how to gauge sharpness using more straightforward, quick methods. In other words, experience tells you that a 200 BESS edge equates to a particular sound as it slices through your favorite catalog paper. A 200-BESS edge is dang sharp. Very sharp. I would venture a guess that most people think they’re getting a sharper edge than reality. I know this was true for me.

My Case for the BESS Sharpness Tester

I bought into the BESS system several years ago because of the simplicity and standardized test media. We MUST have widely available and highly consistent standard test media for this system to work. In this case, it resembles a suture material or monofilament fishing line. Several folks have approximated various off-the-shelf fishing lines as low-cost bulk test media alternatives, but the inconsistencies of nylon monofilament are well-known and documented.

The BESS test media does more than test for relative sharpness vs. a quasi-standard BESS C scale. The test also exposes an improperly de-burred foil edge instantly too. Still, there are flaws with the BESS system that some say can be exploited to achieve lower readings. For example, knowing, for sure, that you have identical test media tension for successive tests takes some special effort. The community overcomes the variable tension concern by using a standard laboratory weight (typically 100 grams) to consistently tighten the line between each new test.

As for me, I use a 100-gram certified calibration weight to tension line when improved consistency is needed. Still, others say quicker downward force yields better results, and others say angling the knife or cutting at either edge of the tensioner also improves the outcome. The challenge has been establishing a reasonable repeatable standard to communicate relative sharpness in a quantifiable manner. Most of the time, I don’t bother since nobody sees my results but me. If I were comparing with another, we would probably work out the precise rules and video record the measurements. Right now, other than cigarette paper push cuts, the BESS standard, method, and test media seem to be the standard to beat.

BESS System Cost

The equipment and test mechanism costs aren’t what I consider ridiculously expensive, at least for entry level, unless you’re particularly frugal. However, depending on the options and test frequency, the BESS system is certainly not what I would call cheap either. Then again, if you are into excellent knives and hand sharpening, I’ll wager you spent a fair amount of money on that stuff.

BESS Fixed Costs vs Consummable Costs

The entry-level PT-50c will set you back around USD 150.00 as of Jan 2022. The Pro is around $180.00, and Industrial PT50A goes for about $269.00 and offers 1g measurement increments if you want more detail—the cost of a decent or real-decent new knife. You get a fair amount of test media and everything required in the kits above. Additional spools of test media are relatively inexpensive, and all the above is available directly from Edge-On-Up online, which is how I bought mine. Many other reputable dealers sell the system online too. It’s worth noting that this is NOT an advertisement for the product, and I do not profit if you elect to buy a BESS PT50 tester. But, I do believe in what the product does and offers me.

The BESS System: No Panacea

Note: Whether you agree with the usefulness of the BESS system, there is no denying that most understand it. Any seasoned sharpener quickly assesses and knows the degree of sharpness and quality of a polished or toothy apex without the BESS scale. We all have our preferred methods of quickly assessing sharpness. Still, having access to the BESS system, or some easily replicable standard, only serves to keep you on top of your game and communicate the quality of your work a little more meaningfully than random paper or arm hair-shaving demonstrations.

By nature, many people do not like to be measured. Ignorance is bliss for some folks, I suppose. That’s ok, as far as I’m concerned. But it does get me riled up when detractors say the test is useless or meaningless. Not only are they wrong, but I can almost guarantee that their edges are not as good as they think, yet they’ll never know. These are the same people who believe in all kinds of myths and misinformation about abrasives and steel. Ok, enough of the soapbox; where was I?

BESS Limitations For Knife Edge Testing

The BESS system measures the effort in grams of pressure for an edge to sever a calibrated material using a push cut. That’s it. That’s exactly what it does. Each measurement is one tiny spot along the blade edge apex. It does not test slicing; at least, the BESS PT50 systems don’t. However, Edge-On-Up has introduced some testers that test slicing and push-cutting sharpness in one system. For that system, you’ll now be forking over some pretty serious cash ($500+) that’s well outside my semi-professional sharpening needs.

Edge Quality, Yes; Durability Not Directly Tested

Further, the PT50 system does not evaluate the durability of a given blade, however it does punish low quality sharpening or deburring with high scores. The BESS PT-50 exposes an improperly de-burred or foil edge easily with a terrible BESS number. When that happens you can easily see the divot where the test media digs into the foil edge (improperly de-burred edge- trust me on this).

Other than exposing foil edges, there is no way to know durability other than to retest manually after iterations of controlled test cuts on something like rope or cardboard and to compare the degradation results over time with other blades sharpened at the same bevel angles. In other words, you can evaluate blade durability by measuring the knife and then test cutting a control material a controlled number of times, using a controlled pressure level, and then retesting to assess impact. There are folks out there that do this sort of thing and report their findings on the Internet. Knife designers, for example, might like to evaluate various steel options for a new knife, and durability testing would help them choose.

So, Exactly How Sharp Is Your Knife?

So, I ask you: how sharp is your knife, exactly? I realize that many people, possibly most people, don’t care beyond having a useful knife to use wherever they want. I get that. However, if you’re among those of us who sometimes obsess over having sharp knives, perhaps you wonder how your edges compare to other sharpeners out there. I see so many videos of people demonstrating their bare arms, shaved faces, and sliced up paper to indicate a serviceable edge.

TBH, that usually works for me too. But, context is rather eye-opening. I found that there is another level of sharp, or “keen” that most people have no idea exists. For me, the curiosity about my own edges got the better of me, and I had to find out. It turns out I was nowhere near as sharp as I thought I was. My edges now are better for it. Now my tools, knives, scissors, and fishing hooks are all exactly as sharp as I need them to be and I can measure every now and to make sure. Quality Assurance? LOL

GL In Your Sharpening Journey

I hope this article has been helpful to you in your knife-sharpening odyssey. I believe BESS is good for some of us obsessive edge types, but it’s certainly not for everybody. Either way, let me know your thoughts on the topic, especially if I got any of this wrong. Just be civil about it 😉 For more articles on a wide variety of topics, please bookmark the site.

K